The wire size chart below shows allowable ampacities of insulated conductors rated up to and including 2000 Volts 60C through 90C 140F through 194F not more than three current. You then multiply the drive pulley diameter x 12 to get 72 or about 7 316 to get to that RPM.

Motor Fan Pulley Sizing For Hvac Physics Forums

About Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy Safety How YouTube works Test new features Press Copyright Contact us Creators.

. For a system with two shafts and two pulleys - as indicated with pulley 1 and 2 in the figure above. I just installed an exhaust blower motor. Notice the airflow should increase 17 for the fan to deliver the required airflow.

Wire Gauge Chart vs Amps vs Length. RV Converter charging 1-8 Amps. Disconnect power from the blower motor by shutting it off at the disconnect box to the unit or unplugging the power source.

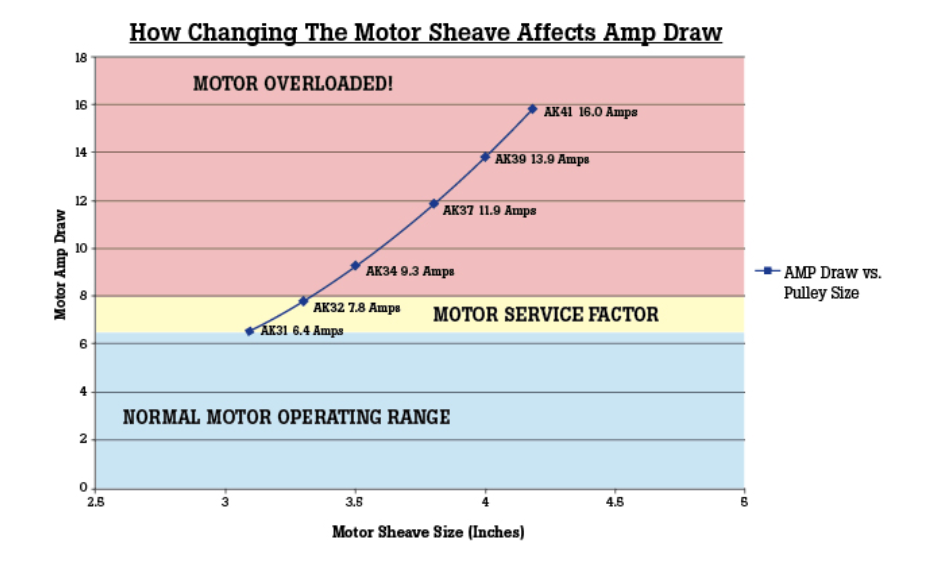

If you know any 3 values Pulley sizes or RPM and need to calculate the 4th enter the 3 known values and hit Calculate to find the. Belt Width mm Face Width mm Bearing centers mm Max. The chart above illustrates the increase in.

1 in 254 mm. The nameplate in Figure. Use this chart to help determine what size wire you should be using based on AMPS being pulled and.

This will also increase load on motor and cause higher Amp draw make sure motor is not overloaded not drawing more. Changing a pulley size or making an adjustment on the motor pulley if it is adjustable will accomplish this. Troys response I would go with a 3hp 1800 rpm as that is what they used from the factory or you could use what is called a cheater motor which would be 34503600 rpm.

Overheating is the leading cause of motor failure. I know if I install a larger diameter pulley on the motor it will slow the blower down. When increasing pulley size always check amp draw immediately after making the change.

Pulley size and amp draw Written By hulmes Sunday March 20 2022 Add. Appliance Amperage Draw Chart. RPM Belt Length Speed Animated Diagrams - Inch.

What will that. The no load for a 75 hp motor 5 amps. 208 volt single phase one hp.

May 1 2013. VFD sizing should always be based on motor current and voltage not hp. Just change the pulley to a smaller.

The Test Procedure. The LOAD determines the current draw. Then multiply the pulley belt diameter of 55-in.

This means the pulley ratio must be 611 to drive the pump correctly. Motor is running 74 amps and I have the belts adjusted on the loose side. Single Belt Transmission - one driving pulley and one driven pulley.

Yes larger motor pulley will increase fan RPM. This pulley experiments is such a fun science project. The most economical and practical pulley to replace is the motor pulley.

D1 n1 d2 n2 1 where. Allowable shaft ø mm Bearing Center Type. For example if the pump RPM is 1070 for full output while the.

Hypothetically speaking if we had a 4 inch pulley on the motor we would require a 655 pulley. Nameplate says 230 volts usable 208 volts 65 amps 230 volts SF 115. Some appliances may require more or less depending on their efficiency and size.

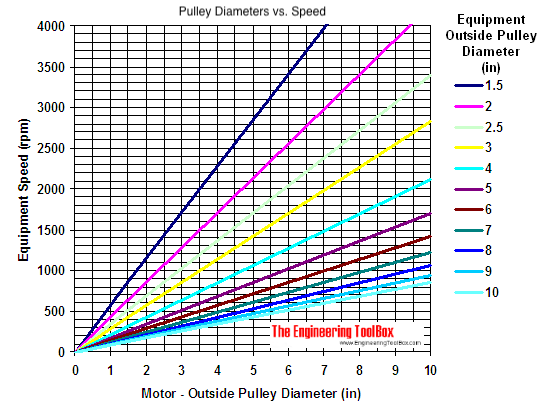

Motor and equipment speed for pulleys with different diameters are indicated in the charts below. A motor operating at higher amperage for an extended time will generate excess heat. Hence the excessive amp draw.

Lets begin with the basics by learning how to read a motor nameplate. The fuse is a 250 volt 2 amp slow blow fuse. Times 117 to find the new belt diameter of 644.

If you know any 3 values Pulley sizes or RPM and need to calculate the 4th enter the 3. February 16 2018 Ryan Electrical. Motor was only rated for max 142 amps 230 volt I reduced the drive pulley size lowered HP required to 3 HP then amps dropped to an.

The simplest way to find the ratio of the required pulley is to divide the driven component pump by RPM. The no load current for a 3 hp motor is about 3 amps. All we would need to do is divide 600 by 500 to come up with 12.

Correctly Sizing A Pump Pulley Sheave All Applications All Pumps

Derale 13740 19 Row Hyper Cool Dual Cool Remote Cooler Remote Compact Cars Dual

New Electric Motor Wiring Basics Diagram Wiringdiagram Diagramming Diagramm Visuals Visualisation Graphical Check M Diagram Car Audio Electrical Diagram

9 Free Band Saw Plans Build Your Own Band Saw Or Saw Mill Bandsaw Woodshop Tools Diy Bandsaw

Fusion Climb Secura Double Aluminum Side Swing Pulley Purple See The Photo Link Even More Details This Is An Affiliat Aluminum Siding Belay Devices Pulley

Is Changing Fan Pulleys A Cost Effective Shortcut To Boost Fan Output The Poultry Site

Motors Speed Vs Pulley Diameter

How To Draw A Sprocket Gear Bike Chain Roller Chain Bmx Bikes

0 comments

Post a Comment